If I knew what was gonna break then it would probably already be broken. Like, If there was a common part that always fails then it would have failed on all of them.

Seems pointless to keep 3 entire microwaves around then, also what are you even doing to your microwaves that makes them fail this much? I have never seen a microwave fail, and I use them all the damn time.

Only parts prone to breaking are the knobs, handles, etc, and those are easier to just 3d print a replacement. If your electrical parts of the microwave have failed, I would assume the rest of the unit is already well past its prime at that point.

but I’ve also had the housing rust out

Bruh what the fuck your microwaves are rusting out? What are you doing to these things.

I’ve had to pull all the guts out of one and put them into another because the one piece that was bad wouldn’t fit properly in the newer housing.

So these arent even exact same models, which makes it even weirder to keep them for spare parts.

And I simply don’t have the time to strip down everything I have in the shed, package, label and identify every part in it.

Which is why you want to gain the skill to identify the key parts worth keeping and get rid of the rest. If you have the time to repair the microwave, you also logically should have the time to prep the parts ahead of time so you arent scrambling to ad-hoc fix the thing when it breaks.

Also the price of nice little bins is crazy

You can 3d print them for like a dollar a pop. And in terms of tools, a 3d printer solves a lot of these types of issues, as instead of having to keep a bunch of spares around, or order new parts, or throw the entire thing out and buy a new one, you can 3d print a lot of replacement parts that are prone to breaking.

And most often its the plastic bits that are the most brittle and most prone to snapping/cracking/breaking over time.

Just an example: I had this giant plastic screw for my 30 year old dishwasher, it snapped clean in half and would have been impossible to replace. 30 minutes with calipers and a script I found to generate screw models by measurements online and my machine was printing away. Another hour later and the screw was done printing, I popped it in and... it worked first try and has been in my dishwasher working fine for the past 2 years. Cost me a whopping 30 cents worth of plastic and 30 minutes of my time.

And then just having all the tools needed is also another problem

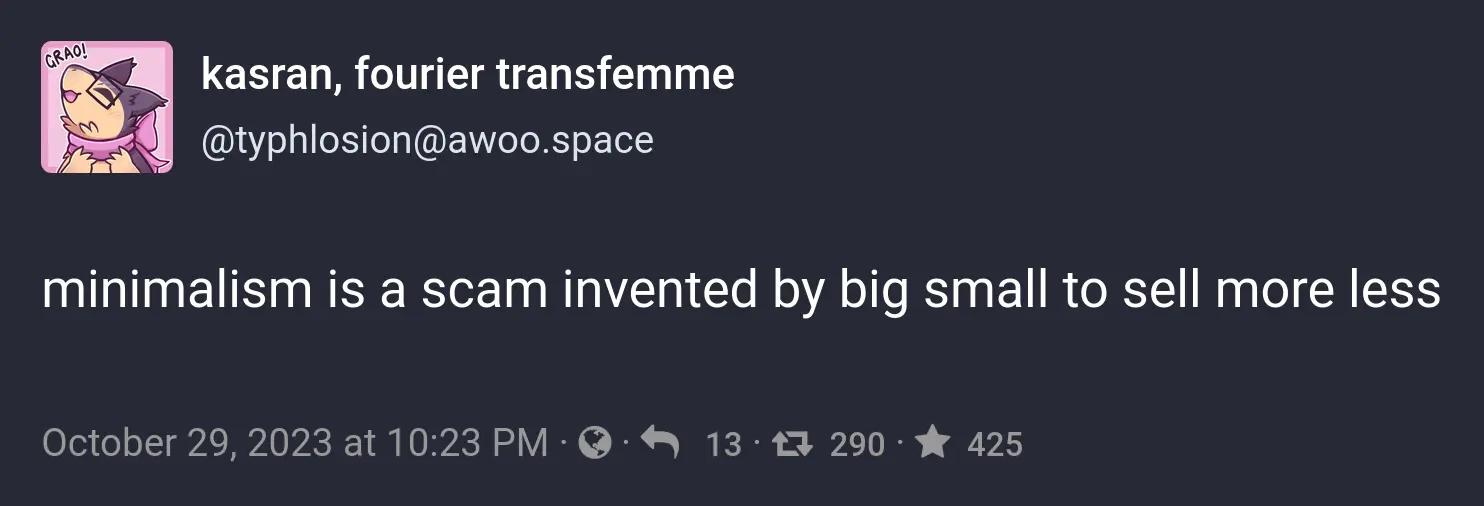

Not really, buying tools you need is acceptable in a minimalist lifestyle. What isnt minimalist is buying a buncha shit you dont need.

There are specific tools that can handle like 99.9% of your use cases, and as long as you get those you should be fine for any ad-hoc work, and the last 0.01% you can rent.

A dremel, hand saw, and power drill can get you really far for a lot of tasks.

renting hand tools usually costs about the same as buying them.

Factually false, especially those 0.01% of tools you only need once for a job. Most tools you have to rent for a couple entire weeks before it costs the same as buying, and some you have to rent for a month or two.

Renting is quite cheap actually.

If you need the same tool again you’re once again spending money.

You usually need it several times in these cases before it was better to just buy it.